SERVICES.

EMERGENCY REPAIRS

Caldervale Machine Tool Engineers offer emergency breakdown repairs. We understand that keeping your machine tools running is very important for production requirements. We aim to respond to emergency breakdowns within 24 hours.

MODERNISATIONS

Caldervale Machine Tool Engineers offer turnkey solutions for machine modernisations. This can be modernising a small part of your machine tool to retrofitting a full control system. Please contact us for a quote.

MACHINE RELOCATIONS

Caldervale Machine Tool Engineers have a great amount of experience in machine tool relocations. We can also offer a machine survey including ballbar tests with print out results before and after the machine tool relocation to show that the machine is back to its original state or better after the relocation.

PLANNED REPAIRS

Caldervale Machine Tool Engineers offer planned repairs to your machine tools which will suit your production requirements.

PLANNED SERVICING

Caldervale Machine Tool Engineers offer tailored service packages to suit your machine tools.

Guarding Solutions

Caldervale Machine Tool Engineers offer guarding solutions for all varieties of machine tools. Please contact us for a quote.

CONTRACT MAINTenance

Caldervale Machine Tool Engineers offer maintenance solutions according to your specific needs. Each service contract is assessed and custom built to meet the individual needs of each company. It can include all machine tools within a factory from the smallest buff to the largest horizontal borer or it can be tailored to suit key or critical machines.

Sales (New and Used)

Caldervale Machine Tool Engineers offer a range of new and used machine tools. Please check our “Used machine tools” section to view what we have in stock. If you are looking for something specific please contact us for a quote

HEIDENHAIN ENC. TEST

We have the ability to test your Heidenhain encoders with our PWM20 test equiptment, encoders can be tested either in line on your machine tool or the encoder can be bench tested.

BALLBAR INSPECTIONS

Caldervale Machine Tool Engineers offer Ballbar tests and inspections using our Renishaw QC20-W equiptment. Ballbar testing provides a simple, rapid check of a CNC machine tool’s positioning performance to recognised international standards (e.g. ISO, ANSI/ASME etc) allowing users to benchmark and track the performance of their machines and to quickly diagnose problems that may require maintenance and the error sources that produce them.

LASER CALIBRATION

Caldervale Machine Tool Engineers offer laser calibration and inspection of your machine tools. Including Linear, Straightness and Flatness checks. Linear measurement accuracy is an assured ±0.5 ppm thanks to a precision stabilised laser source and accurate environmental compensation. Readings can be taken at up to 50 kHz, with a maximum linear measurement speed of 4 m/s and a linear resolution of 1 nm, even at maximum speed. All measurement options (not just linear) are based on interferometric measurements, giving confidence in the accuracy of the data recorded.

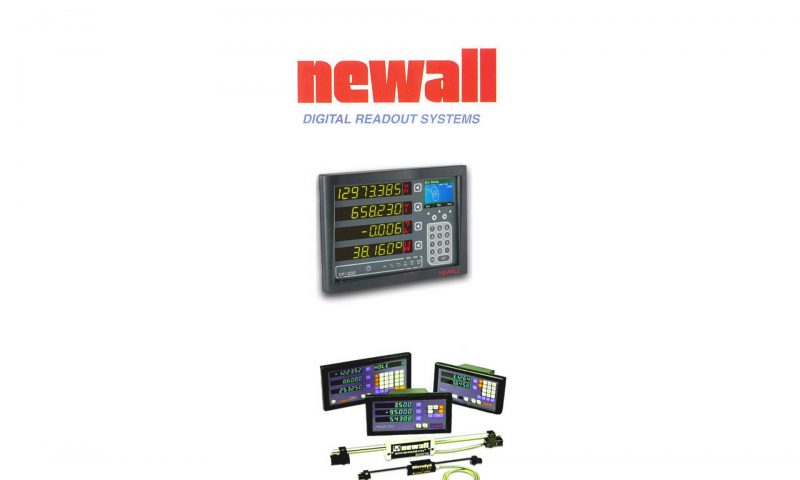

DIGITAL READOUTS

We can offer spares for your existing system or complete DRO systems to suit your machine tools. We can also repair a wide range of DRO systems. Please contact us for a quote.